top of page

KEY FEATURES

DOCKING MADE EASY

Hēsion Guide System® (HGS) is a simple and intuitive interface that positions vehicles for Stinger®. Think of HGS's rugged interface as an externally mounted backup guide. Tested by drivers of all experiences, HGS provides easy and clear directions so a driver can quickly position the Ready-Mix truck.

1

2

3

NO MODIFICATIONS

Once a ready-mix truck is docked, Stinger® will complete the washout process in 4 minutes. Stinger's® unique, patented design is the ONLY washout system that can reach all areas of the ready-mix drum without modifications to the chute or hopper. No more safety hazards associated with climbing onto the truck, dismantling the hopper, or exposure to silica.

Incorporating Serum®, in the last washout before the end of day provides protection from build-up that lasts the whole day.

CLEANING POWER

Specially designed heads with using only 150 PSI deliver enough cleaning power to blast away buildup from the very bottom to the top of the Ready-Mix drum, even the back of the fins where most lance style washout systems can't.

Delivery the ultimate cleaning solution by incorporating Serum® into the washout solution at the end of each workday and be amazed at how clean drums can be.

Watch the video to see the drum after a washout.

1 BUTTON TO RULE THEM ALL

Stinger® is designed with no special license or skills needed for an operator. Easy to learn with remote monitoring, only 1 operator is needed.

Park the truck and push the button. It's that simple.

There is no tooling changeout, modifications to the Ready-mix truck, adding or removing equipment.

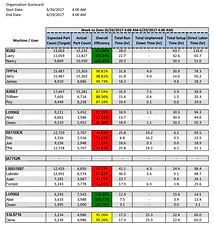

BUSINESS INTELLIGENCE

Stinger® includes an intelligent monitoring system tracks data such as the truck number, time, length of process; volume of water used, pressure, mixture, and machine conditions.

Access the data online in real-time and utilize Core Trace® to analyze and build actionable dashboards and KPIs.

Utilize the data for process verification and validation, preventive and predictive maintenance. Capture mixture and application consistency with Serum®.

Stinger® can be up-fitted to include a video monitoring feed that enables monitoring of the conditions inside the drum during the washout process and document the washout process.

QUICK SETUP

Site requirements are as follows:

-

480VAC, 35A, 60HZ Power

-

Fresh or Recycled Water Supply with 3-inch Cam Lock Fitting

-

Outfall Area for Drum Water Discharge

-

A minimum of a 6.5 feet x 18 feed (2-meter x 5.5-meter) space behind the truck washing location

-

45 feet (14 meters) of Overhead Clearance

Stinger® can be calibrated, up and running in a less than a day*.

* depending on the number of trucks programmed for Stinger®

bottom of page